Hi there, today it’s going to be about some really special appliances of 3d printing, this brand new additive manufacturing technology, which has been applied in the rapid prototyping industry for many years now, but in the last couple of months, it seems to bless the housing and building industry as well.

The advantages of using 3D printing technology in building industry would be quicker construction, lower labor costs, and less waste produced. It is also a potential way of building extraterrestrial structures on the Moon or other planets where environmental conditions are less conducive to human labor-intensive building practices. The layer by layer building technique of the most common 3D printing techniques offers a large scale of opportunities for architects and designers, but unfortunately, they haven’t got the chance for experimenting because the usual 3D printers have a build volume of about 300 cubic inches so it isn’t enough for some large scale or 1:1 prototypes or building structures.

That scale fits for the most 3D printed projects in almost every scene, such as jewelry, shoes, furniture, and 3D printed art work. But there are already some really inspirational and progressive experiments and researches at Loughborough University (UK) which is inspired by 3D printing with concrete and which is said to be capable of producing full sized building components with a degree of customization that has not yet been seen. It could create a new era of architecture that is adapted to the environment and fully integrated with engineering function. It sounds pretty weird, doesn’t it?

Research is under way to flexibly construct commercial and private habitation in around 20 hours, with built-in plumbing and electrical facilities, in one continuous build, using large 3D printers. Working versions of 3D printing building technology are already printing 2 metres (6 ft 7 in) of building material per hour as of January 2013, with the next-generation printers capable of 3.5 metres (11 ft) per hour, sufficient to complete a building in a week.

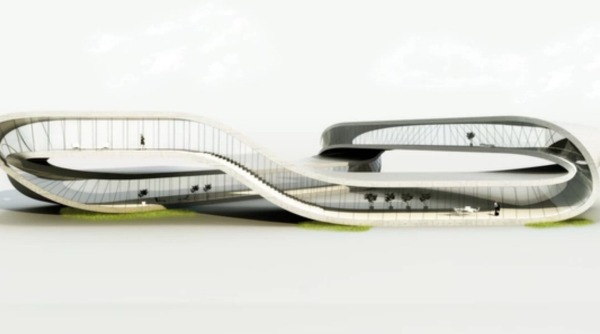

A dutch architect is planning on constructing a two-story, futuristic “Landscape House” using a custom-designed 3D printer. He uses a D-Shape printer, which combines thin layers of sand with some bonding material to create a similar finish to marble. The building, then, will be 3D printed in chunks — about 20 feet by 30 feet — and be constructed from the ground up. That’s what additive fabrication is all about, isn’t it? Janjaap Ruijssenaars’s 3D printed building is scheduled to be built in 2014.

“ The Landscape House couldn’t be built with conventional technology — the 3D printed frame will be one huge piece of rock, entirely seamless, with steel and glass extras installed on the sides. Its shape is meant to “celebrate landscape”, but it’s also a demonstration of what might be considered the efficiencies of 3D printing rather than any kind of revolution. “ (Ruijssenaars)

Let’s conitnue with another awesome 3D printed architectural project! Do you know Softkill Design‘s Protohouse for a great example of additive construction that really would be impossible with bricks and mortar and other traditional building materials? Let me introduce you this amazing concept of this complex organic structure, which can remind you on sci-fi scenes.

The Protohouse of Softkill Design experiments with the architectural potential of the latest Selective Laser Sintering technologies, pushing the boundaries of huge scale 3D printing by computational designing using parametric and generative algorithms that can micro-organize the printed material itself. With the support of the huge 3D printing company Materialise, Softkill Design fabricated a high resolution prototype of a 3D printed building at 1:33 scale. The 3D printed model consists of 30 precisely detailed fibrous pieces which can be easily assembled into one continuous cantilevering structure, without need for any adhesive material. The arrangement of 700 micron radius fibres displays a wide range of flexible and dynamic architectural textures and the capability to fabricate built-in architectural elements, such as structure, furniture, stairs, and façade, all in one instance. That will really inspire the contemporary architecture, just you wait!

And I want to introduce an other awesome concept, the project came from the MIT Media Lab, and it’s actually a progressive and experimental collaboration between computational architecture and bio-engineering. Neri Oxman and her team at MIT has built a pavilion using silkworms and the technology of 3D printing: just check out this awesome video about the project, it really looks amazing!

SILK PAVILION from Mediated Matter Group on Vimeo.